Darigold

Caldwell, Idaho

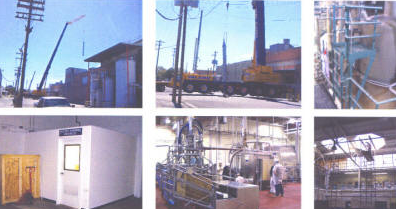

Over the years, Leavitt Engineering has provided structural and consulting engineering for various projects at Darigold's Caldwell, Idaho plant. In 2007, we provided design construct and construction management services for several major plant additions and improvements. In early spring of 2007, we installed a new triple stack, hold tube, fusion heater, and cooling tower.

Installation of new equipment in a busy existing plant is always a complicated process. Special and unique procedures had to be designed and implemented to snake the new equipment into the existing plant. Our team designed, fabricated, and installed additional structural foundations, support framing, and access to the equipment, which was all required to support and operate the new equipment.

During the following summer, we constructed two large mat foundations within the plant to support 40,000 gallon silos. Vinyl containment walls were constructed around the project within the plant to environmentally protect the ongoing dry milk production operations. Structural shoring and bracing was constructed to temporarily support the roof while the roof framing was reconstructed to cut two 14 foot diameter openings for the silos. The silos were lifted and installed down through the roof openings allowing their top to project through the roof. Leavitt Engineering designed and constructed the roof alterations and supervised the silo installation, roof repairs, and silo anchorage.

The fall 2007 Butter Plant addition was our biggest and most challenging project. Major structural repairs and upgrades were required to bring the existing warehouse and cooler into compliance with current ASKA requirements. We demolished existing walls, replaced the existing floor drainage systems, built two new in-plant offices and a lab, installed equipment, removed existing tanks, added new walls, window, and doors, made various repairs, and painted the repairs and improvements. The Butter Plant addition included new butter churns, an automatic salt metering dispenser, conveyors, packaging, a pallet stacking robot, wrapping, and cooling operations.

The following winter, projects included structural design of foundations and a new concrete containment structure for the vertical and horizontal sludge tanks. Topographic survey and civil design of storm drainage were included. Leavitt Engineering also designed and detailed a new spiral staircase to provide multi-story access in the plant.